our technologies

Aluminum die casting

Aluminum die casting

This technology involves the manufacture of high quality castings. A chill mold is a collapsible mold for casting made of heat-resistant steels with a special coating. It is poured with metal, which fills the mold under the action of gravity. After the crystallization of aluminum, the mold is opened and the casting is removed. This technology is used for the production of large batches.

Casting in CHM (cold hardening mixes)

Casting in CHM (cold hardening mixes)

With this method, a special molding sand is used, consisting of a liquid composition and a filler. Solidification takes place in the core box or on the model. This technology is widely used for cases with low requirements for tolerances and surface finish. This technology is suitable for small-scale production.

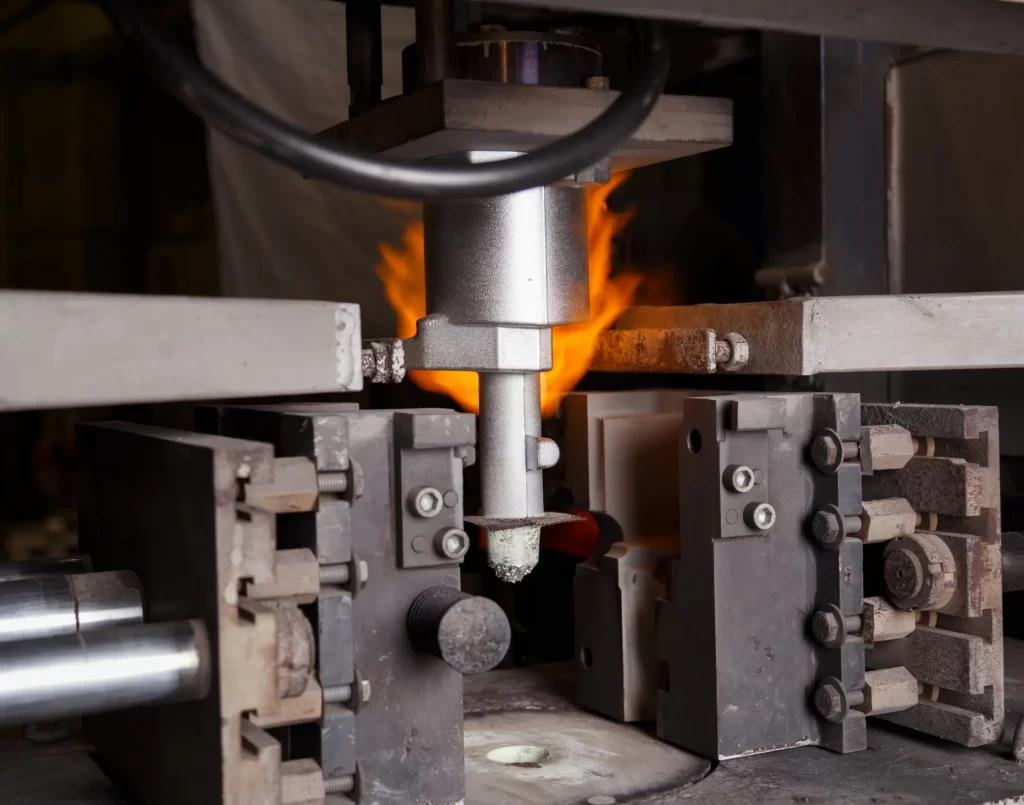

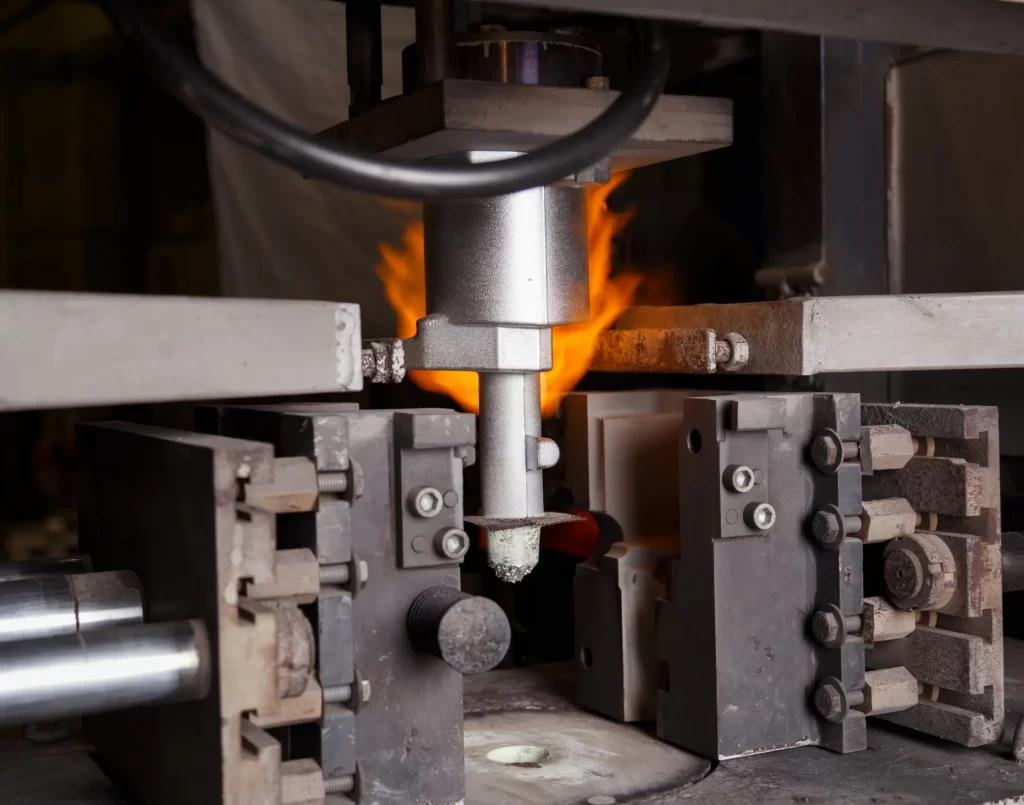

Low pressure casting

Low pressure casting

It is used to obtain castings with high characteristics in terms of surface quality with minimal allowances for machining. Filling the mold is carried out by supplying liquid aluminum with compressed air. This ensures smooth filling of the mold, purity of the melt and, as a result, very high casting quality.